torsion test carbon fiber|Characterization and analysis of torsion property of carbon fiber : wholesaler The global fiber kinking theory for the estimation of the axial compressive strength of a UD CFRP was modified for the local fiber kinking theory. Then, the nonlinear shear stress–strain curves of the composite and matrix were measured by the V-notched beam test, in-plane shear test, and torsion test.

webSource citation. , database and images (: accessed ), memorial page for Renata Igorevna “Rina Palenkova” Kambolina (18 Dec 1998–23 Nov 2015), Find a Grave Memorial ID , citing Morskoye Kladbishche, Vladivostok, Primorsky Krai, Russia; Maintained by Prometheus (contributor ). Renata perished at the age of 17 by suicide.

{plog:ftitle_list}

Grand Theft Auto: Vice City expandiu o cenário e a música

Experimental and Theoretical Evaluations of the Iosipescu

The Iosipescu shear test with a modified Wyoming test fixture (ASTM D5379-93) was investigated experimentally and theoretically as a mean for determining the in-plane shear .This study established a torsion testing method for carbon fiber bundle combined epoxy resin and investigated torsional properties of several kinds of carbon fiber with different epoxy . A torsion-balance tester has been developed to measure the torsional properties of single micron-diameter fibers/wires. The design of the tester allows one to perform .

Torsion Test of Fiber Carbon Composite Core Rod Used in Overhead Stranded Wires @article{Yu2015TorsionTO, title={Torsion Test of Fiber Carbon Composite Core Rod Used in Overhead Stranded Wires}, author={Hong Yun Yu and Rui Li and Miao Qian and Guo Li and Min Yu and Zhi Hua Zhu and Zhou Xuan Li}, journal={Applied Mechanics and Materials}, .

Fiber-reinforced polymer-matrix composites have been widely applied in various areas due to their excellent mechanical properties. In this study, carbon fiber-reinforced polymer-matrix composites and glass fiber-reinforced polymer-matrix composites failure tests under quasi static torsion have been demonstrated by using spiral notch torsion test methodology.

The global fiber kinking theory for the estimation of the axial compressive strength of a UD CFRP was modified for the local fiber kinking theory. Then, the nonlinear shear stress–strain curves of the composite and matrix were measured by the V-notched beam test, in-plane shear test, and torsion test. Carbon fiber testing is a set of various different tests that researchers use to characterize the properties of carbon fiber. The results for the testing are used to aid the manufacturer and developers' decisions selecting and designing material composites, manufacturing processes, and for ensured safety and integrity. Comparison of torsion tube and iosipescu in-plane shear test results for a carbon fiber-reinforced epoxy composite. Compos, 16 (3) (1985), pp. 220-224. View PDF View article . Investigating fracture behavior of polymer and polymeric composite materials using spiral notch torsion test. Eng Fract Mech, 101 (2013), pp. 109-128. View PDF View .

THE IOSIPESCU SHEAR TEST FOR HYBRID FIBER COMPOSITES Jianmei He, Martin Y.M. Chiang, Walter McDonough and Donald L. Hunston . walled tube test and the solid rod torsion test [2,3], the Iosipescu shear test uses a flat specimen . volume fraction of epoxy matrix in glass and carbon fiber tows is the same as with the experiments at 30%, while .

The type of carbon fiber material chosen in this paper is T700-12 K, and its density is 1.76 g/cm3. The matrix is JL-235 and JH-238 epoxy resin adhesive provided by Changshu Jiafa Chemical Company, with densities of 1.14 g/cm3 and 0.92 g/cm3, respectively. The epoxy resin has low viscosity and high fluidity. Carbon fiber-reinforced composites exhibit excellent mechanical properties for a variety of applications. Using the spirally notched specimens, we demonstrate how unidirectional carbon fiber-reinforced polymeric composite specimens with different fiber orientations fail under quasistatic torsion. By collecting data at 200,000 points per second, type I specimens .

As the mechanical properties of carbon fiber are much higher than those of glass fiber . this area is more prone to shear failure in the torsion test. The undulated fiber bundles along the winding direction are compressed, leading to the gradual collapse of the internal matrix and the failure of fiber monofilaments under pressure. . Carbon fiber reinforced composites are being increasingly used in applications requiring low weight with high strength and stiffness. In many widely adopted out-of-autoclave (OOA) processes such as vacuum infusion processing (VIP or VARTM) and resin transfer molding (RTM), carbon fiber fabrics are most commonly used for rapid laminate thickness .Deformation and failure of carbon fiber composite specimens with embedded defects during tension-torsion test. . .3221/IGF-ESIS.46.27 Deformation and failure of carbon fiber composite specimens with embedded defects during tension-torsion test Valery E. Wildemann, Tatyana V. Tretyakova, Elena M. Strungar, Mikhail P. Tretyakov Center of . Figure 4. 2 nd Hybrit drive shaft static torsion test. . To avoid potential risks, filament winding with integrated flanges was proposed to prepare carbon fiber-reinforced composite (CFRP) drive .

To date, the characterization of mode I, II and their mixed-mode interlaminar (delamination) failure is of a great concern in classical fiber composites reinforced with carbon fibers [[5], [6], [7]] and glass fibers [8].Hosseini et al. [3, 4] inserted mat layers at the delamination interface of twill woven glass/epoxy composites.Both initiation and steady-state fracture .This torsion spring is designed for an ultralight aircraft engine transmission to absorb torque fluctuations.Manufactured by "hand filament winding". Materia.

Direct measurement of torsional properties of single fibers

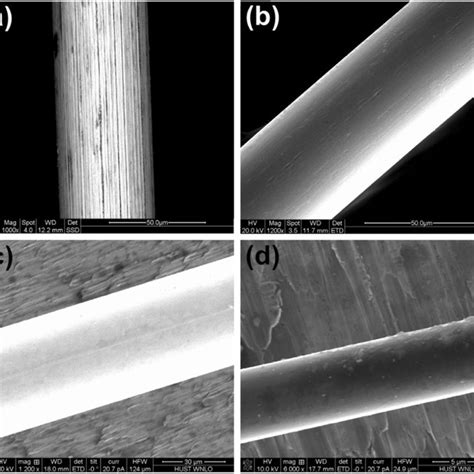

The number of torsion turns and twist angle at fracture from the direct torsion failure test were defined to characterize the torsion-bearing capacity of single carbon fiber. The characteristic transverse wave is clearly observed for the carbon fiber. For this particular test the transverse wave velocity measured was 332 m/s. Download: Download high-res image (277KB) Download: Download full-size image; . As with the through-thickness tension tests, the Z-direction torsion test data were used to calibrate . Total deformation for bending test 1 layer From Figure 9, shows graphic of total deformation that happens against the layers of composite with three variants of fiber orientation and six variants . A novel approach for evaluating the torsional performance of single carbon fiber filament was established based on a self-designed apparatus. The number of torsion turns and twist angle at fracture from the direct torsion failure test were defined to characterize the torsion-bearing capacity of single carbon fiber.

This study established a torsion testing method for carbon fiber bundle combined epoxy resin and investigated torsional properties of several kinds of carbon fiber with different epoxy matrix. . observation on fractured sample and single fiber pull-out test were carried out to illustrate the relationship between torsion property and the .

Download Citation | Study of the Design and Torsion Performance for Carbon Fiber Composite Material Automobile Drive Shaft | Based on the classical laminate theory, the stacking structure and its . In this study, carbon fiber-reinforced polymer-matrix composites and glass fiber-reinforced polymer-matrix composites failure tests under quasi static torsion have been demonstrated by using .Torsion Testing of Composite Drive Shafts. Back; Home; Products. Materials Testing. . made of carbon and polymer fiber that are designed to break into small fiber fragments upon failure, increasing safety. Composite driveshafts are also lighter weight (than typical steel) with higher torque capacity, higher rpm value, and reduced noise and . In this work, the distribution of the strain energy release rate (SERR) at the crack front of carbon fiber-reinforced polymer laminates with elastic coupling is analyzed using the edge ring crack torsion (ERCT) test configuration. The SERR at the delamination front is calculated by virtual crack closure technique (VCCT).

Engineers apply the knowledge of math & science to design and manufacture maintainable systems used to solve specific problems. AskEngineers is a forum for questions about the technologies, standards, and processes used to design & build these systems, as well as for questions about the engineering profession and its many disciplines. Torsion test was simul ated to identify maximum deflection oc curred . Sound transmission loss test results for the a few carbon fiber composite panels are presented to highlight the high .

The most common test methods are (i) proportional axial tensile and torsion tests on tubular specimens [18], (ii) bi-axial tensile tests applied to the arms of a flat cruciform specimen [19] and (iii) Arcan tests [20]. Despite of the complexity concerning both specimen preparation and tests setting up, their application on composite materials . The spiral notch torsion test (SNTT) has been a recent breakthrough in measuring fracture toughness for different materials, including metals, ceramics, concrete, and polymers composites.

AUD-20221223-WA0004 LRC Lyrics - Donwload, Copy or Adapt easily to your Music LRC contents are synchronized by Megalobiz Users via our LRC Generator and controlled by Megalobiz Staff. You may find multiple LRC for the same music and some LRC may not be formatted properly.

torsion test carbon fiber|Characterization and analysis of torsion property of carbon fiber